When rubber materials succumb to the test of time or external factors, unsightly cracks can mar their surfaces, compromising their integrity and performance. Whether it’s a cherished rubber boat essential for aquatic adventures or weather-worn rubber seals that safeguard your home from the elements, these cracks demand prompt attention. Understanding the effective repair and protection strategies for cracked rubber is the key to restoring and extending its functionality.

Image: pickedwatch.com

Delving into Rubber’s Composition and Vulnerabilities

Rubber, a versatile and durable material, is renowned for its elasticity and resilience. However, despite its inherent strengths, it is not immune to the degrading effects of time, exposure to harsh elements, and mechanical wear. These factors can lead to the dreaded cracking of rubber surfaces, causing a multitude of problems from water leakage to impaired performance.

The chemical structure of rubber plays a vital role in comprehending its susceptibility to cracking. Rubber is essentially a polymer, composed of long chains of repeating units known as monomers. These chains are cross-linked together, creating a strong network that provides rubber with its exceptional properties. However, the bonds between these chains can weaken over time, particularly when exposed to environmental stressors like extreme temperatures, UV radiation, and ozone.

Cracked Rubber: Diagnosis and Prevention

Detecting cracked rubber is a matter of diligent observation. Inspect rubber surfaces meticulously for any visible signs of splits, fissures, or breaks. Pay close attention to areas subject to constant stress, friction, or exposure to extreme conditions.

Preventive measures go a long way in safeguarding rubber from premature cracking. Shield rubber from direct sunlight, as UV radiation can wreak havoc on its molecular structure. Extreme temperatures, whether scorching heat or bone-chilling cold, can also weaken rubber, making it more susceptible to cracking. Ozone, a colorless gas prevalent in the Earth’s atmosphere, is another nemesis of rubber, causing it to deteriorate and crack. Limit rubber’s exposure to ozone by storing it in airtight containers or utilizing ozone-resistant compounds.

First Aid for Cracked Rubber: Effective Repairs that Restore Performance

When cracks rear their unsightly heads, swift action is essential to mitigate further damage and restore functionality. An array of effective repair options awaits, depending on the extent and location of the cracks, as well as the type of rubber involved.

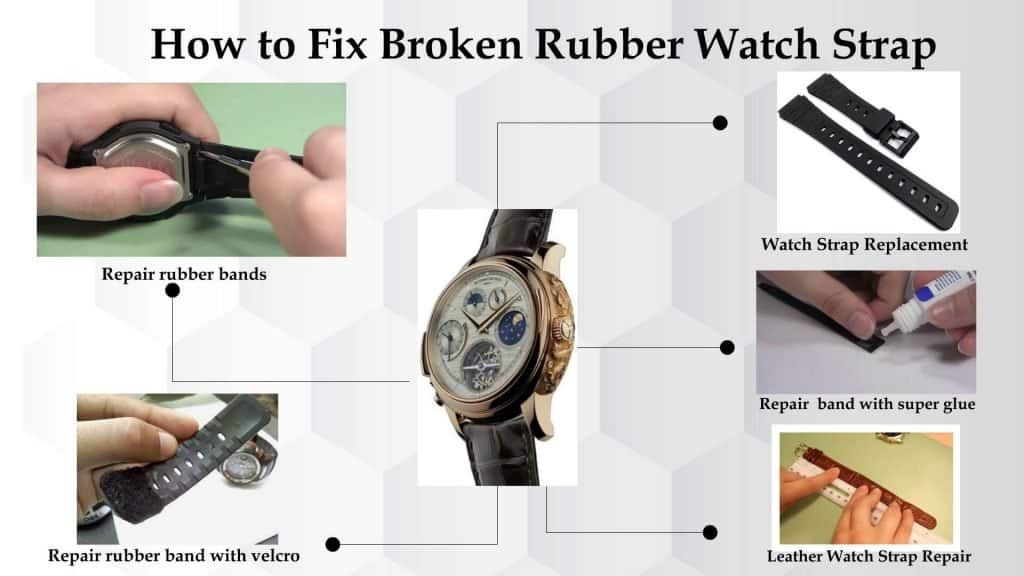

For minor cracks, simple adhesive solutions may suffice. Choose adhesives specifically designed for rubber, ensuring a strong and durable bond. Thoroughly clean and dry the cracked surface before applying the adhesive sparingly. Press the edges of the crack together and maintain pressure until the adhesive cures.

More extensive cracks might warrant the use of rubber patches. These patches, available in various sizes and shapes, provide a more robust repair solution. Select a patch that overlaps the crack by at least an inch on all sides. Clean and dry both the patch and the cracked surface, then apply a thin layer of contact cement to both surfaces. Allow the cement to become tacky, then carefully align the patch over the crack and press firmly. Use a weight or clamp to ensure proper adhesion while the cement dries.

For deep or complex cracks, more involved repair techniques may be necessary, such as vulcanization or welding. Vulcanization involves heating the rubber under pressure, initiating a chemical reaction that strengthens the bonds between rubber chains and restores its integrity. Rubber welding, on the other hand, utilizes specialized equipment to fuse the cracked edges together, creating a permanent and durable repair.

Image: www.wikihow.com

Protective Measures: Shielding Rubber from Future Cracks

Once cracked rubber has been repaired, proactive steps can be taken to prevent future occurrences. Regular cleaning and maintenance go a long way in preserving rubber’s pristine condition. Use mild soap and water to gently cleanse rubber surfaces, avoiding harsh chemicals or abrasive cleaners. Thoroughly dry rubber components after cleaning to prevent moisture buildup, which can weaken the material.

Protective coatings provide an additional layer of defense against environmental factors that contribute to cracking. These coatings can be applied directly to rubber surfaces, forming a barrier against UV radiation, ozone, and extreme temperatures. Choose coatings specifically formulated for rubber to ensure compatibility and long-lasting protection.

How To Fix Cracked Rubber

Conclusion

Cracked rubber need not spell doom for your prized possessions. Armed with the knowledge of effective repair techniques and proactive protection strategies, you can restore and maintain the integrity of rubber materials. Whether it’s a trusty rubber boat, weather-resistant seals, or any other rubber component, proper care extends its lifespan and ensures optimal performance, allowing you to savor the benefits of this versatile material for years to come.